Basalt fiber concrete, facades made from pollution, 3D-printed steel, aluminum foam, glass bricks—these are the ‘supermaterials’ not of tomorrow, but, according to a new exhibition at London’s Building Centre, today. SuperMaterial showcases not only the highly experimental and cutting edge, but also products that are currently available to use and build with.

One example is basalt fiber concrete from Techniker Engineers and Cornish Concrete Products. It combines the two types of rock to provide concrete the strength and thermal conductivity it wouldn’t normally have. In the exhibition, an engineer has used it as a molded structure to show how it can disperse heat in new ways. The result is a passive tool that moves heat around a room, controlling where it’s hot and cool without the need for energy-intensive air conditioning.

Videos by VICE

Facade made of pollution

A facade created by Made of Air, who specialize in carbon-negative products, is one example of a commercially-available material. The facade is essentially made from compressed pollution from felled trees which have been burnt in a pyrolysis kiln. This process produces energy along with biochar, a waste material that takes millennia to decompose. By locking the carbon in, they’ve created a durable facade for buildings that utilizes CO2 that would ordinarily go into the atmosphere.

Although different in composition and effect, the one thing these and the others materials in the show share is a cradle-to-cradle, sustainable design approach. Using biomimetics and upcycling to solve problems, they can increase durability and efficiency, resulting in products that are more environmentally sound.

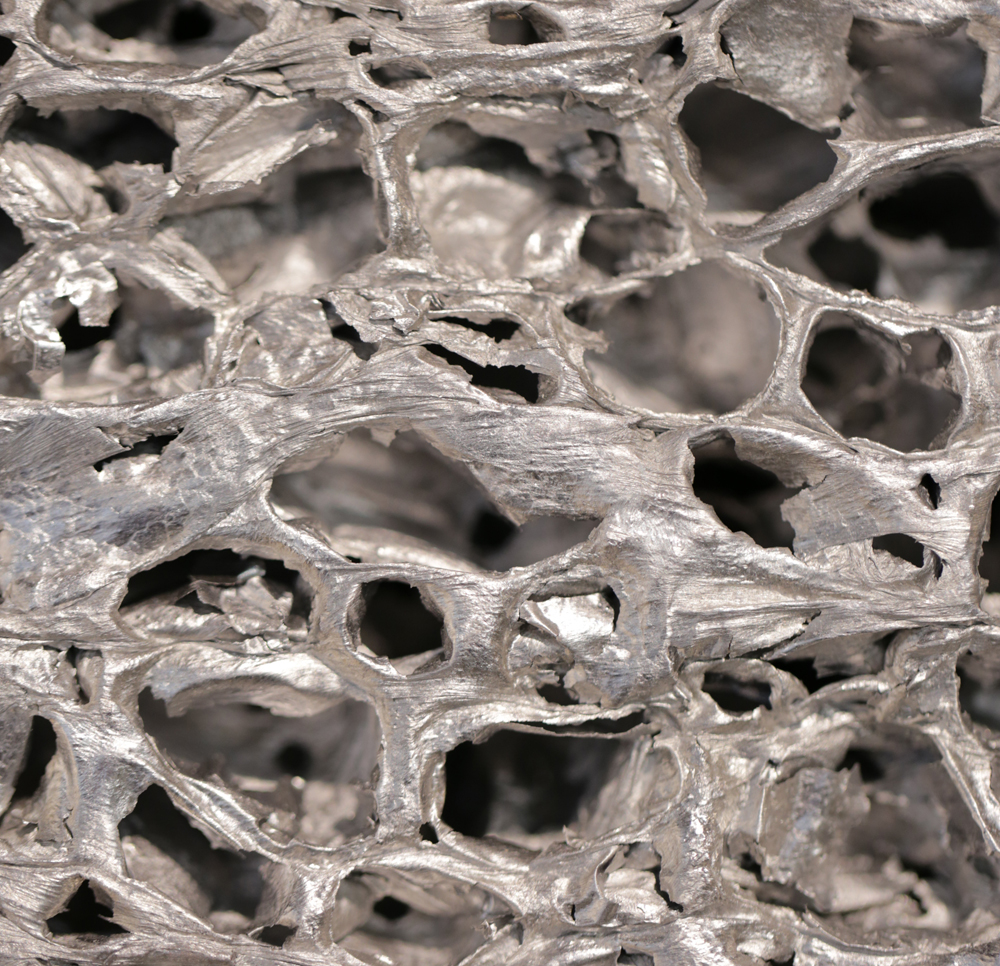

Aluminum foam

“There seems to be quite a lot of excitement about new materials,” Lewis Blackwell, the exhibition’s curator, tells Creators. “We’ve come into a new phase of discovery about materials and the potential of new science and ideas. For example, graphene, a material we didn’t know existed was right in front of us and now we’re only just beginning to see what we can do with it.”

Graphene ink and paint are present in the exhibition. The hyper-thin material gives the mediums superconductivity, meaning that a painted surface could become a conducting screen. Graphene paint also makes a surface radiation-proof, so it could be used in, say, hospitals, defense establishments, or even classrooms or cinemas where you don’t want people using their phones. Future uses could include a graphene film, which could encase a glass building, giving it a giant, changing skin, like a chameleon.

3D printed steel nodes

3D printing is, of course, also represented, and the pieces range from Gaudi-esque 3D-printed steel to the gothic, HR Giger-esque sandstone forms of Michael Hansmeyer‘s Digital Grotesque computational architecture. As well as arresting designs, 3D printing allows for a lot less material to be used, so for steel it cuts waste, making it cheaper to use and is lighter but retains its strength—apply it to a skyscraper and you could build higher and in more variant forms.

Another ingenious but seemingly simple product is an acrylic polymer soil stabilizer made by an American company called Aggrebind. It can be sprayed on dirt roads, millions of miles of which are in countries all across the world, as a cheap, non-toxic, and biodegradable way to harden such a surface. It won’t get washed away in rainy seasons and if it is destroyed by earthquakes, it can be reapplied. It’s in its early days, but, like a lot of these materials, what’s also stopping it from being adopted on a wider scale is the lobbying power of other industries, like tarmac and concrete, who have interests which the soil stabilizer undermines.

“The status quo has a lot of power,” notes Blackwell. “Not because it’s a good idea but because a lot of people have a financial interest in the bad stuff.”

Transparent wood

Glass bricks and transparent wood, briquettes and insulation made with stone wool formed from volcanic lava, are here too. There are bioplastics made from seafood waste—lobster and prawn shells—and architectural textiles made from microbial cellulose harvested from urban algae. EcoLogicStudio are experimenting with the latter and hope, eventually, to use them on an industrial scale.

Stone wool insulation

It all points to a brighter future where buildings and their materials could be a lot greener and more eco-friendly. The question is, how soon will it all be embraced?

“By handling materials differently we can have the potential to do some amazing and positive things, our materials could be making our cities better,” explains Blackwell. “Our buildings could be helping deal with food issues, we could be generating energy in such clean ways, just by a slight adaptation in our environment. Not by changing our way of life that much. That sort of sci-fi future is not some way off thing, it’s here. We just need to join up the bits, we have the materials, we have the products, we just need to encourage the adoption of these things.”

ecoLogicStudio Microbial cellulose prototype

SuperMaterial is on now until April 28, 2017 at The Building Centre, Store Street, London, WC1E 7BT.

Related:

Architects Designed an Entirely 3D Printed Room—And It Looks Like Something Out of Alien

“Reversible Concrete” Is Ready to Revolutionize Temporary Architecture