In early 2019, the L train in New York City will shut down for 15 months to repair damage caused during Hurricane Sandy. Leading up to the closure, VICE will be providing relevant updates and policy proposals, as well as profiles of community members and businesses along the affected route in a series we’re calling Tunnel Vision. Read more about the project here .

On Monday morning, New York City’s subway system had another meltdown. This time, it was a signal problem at Rockefeller Center and an investigation in Downtown Manhattan, which caused a butterfly effect that left a number of lines stalled underground. “Happy Monday morning @NYCTSubway!” one rider wrote on Twitter, with a photo of a crammed subway platform attached. “Fix this shit.”

Videos by VICE

Often times when we think about subways, these are the most visible pressure points—the signal failures, the overcrowding, the slugging trains, etc. But so many of those problems are linked to the infrastructure itself. As the world’s largest subway system, New York has more than 800 miles of track running through it, meaning that the possibilities for failure are far greater than your average city.

And nowhere is that area more vulnerable than under water.

The New York City subway system has 16 subway tunnel connections underneath water bodies, if we’re counting smaller gaps, like the Newtown Creek and Harlem River. That number grows if we add in the tunnels for the Long Island Rail Road, PATH Train, New Jersey Transit, and Amtrak. When Hurricane Sandy hit, in 2012, a large number of those tunnels were flooded, disabling them entirely until workers were able to pump the water out. The Montague Street Tunnel, which takes the N and R trains between Manhattan and Brooklyn underneath the East River, had to be shut down for 13 months, for complete reconstruction. The Canarsie Tube, which transports the L, now faces a similar fate.

But to understand why, or how, these tunnels became so vulnerable, it takes understanding a question that subway riders (myself absolutely included) often do not ask ourselves—how were they even built in the first place?

When I posed this question to Michael Horodniceanu, he immediately made a clarification: The subway tunnels in New York are not necessarily “underwater,” but rather, underneath the riverbed. Except, he adds, the 63rd Street Tunnel, which carries the F train to Roosevelt Island. That one was precast in the South, floated up to New York, and quite literally dropped into trenches dug into the East River, with dirt, stone, and concrete slabs placed on top over time. (So if you dive deep enough, you’d hit the tunnel? “No, because they’re all covered,” he told me. I know, dumb question.)

Horodniceanu would know—for nine years, he served as the head of Capital Construction for the Metropolitan Transit Authority (MTA), overseeing two of the system’s largest expansions in decades: the 7 train extension to Hudson Yards, and the first phase of the Second Avenue Subway (He stepped down this year.) But those, of course, were built in the 21st century, using modern technology that wasn’t available at the turn of the 20th, when most of the subway system as we know it was constructed.

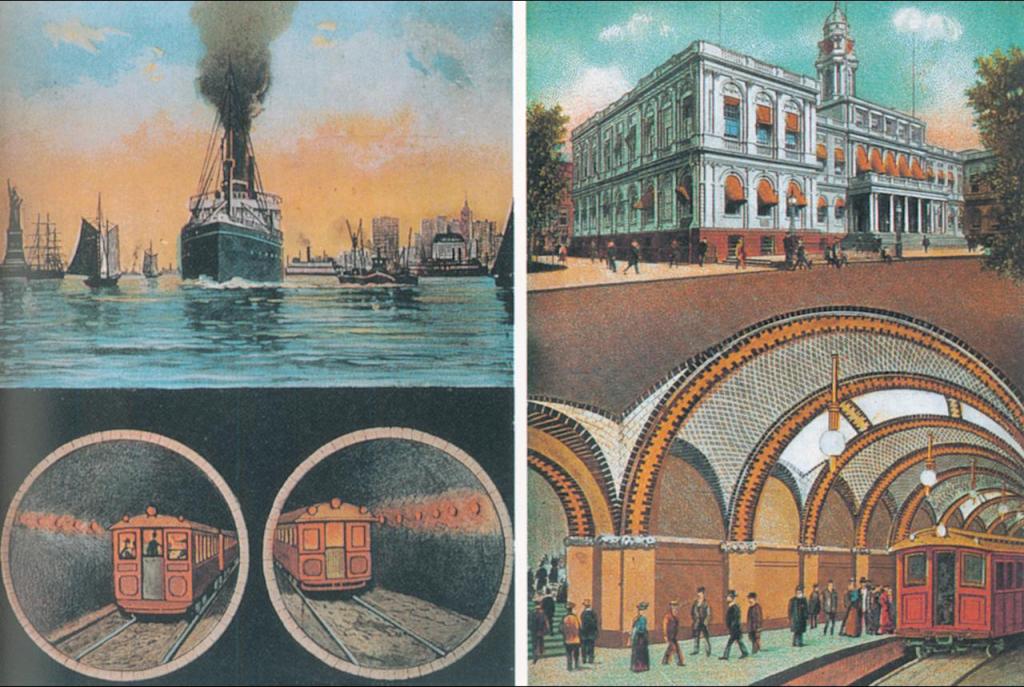

The Canarsie Tube, opened in 1924, was built the same way most of the city’s subway tunnels were, says Horodniceanu. Workers would dig by hand through the riverbed, placing cast-iron rings around them as they went. The soft mud was easy to dig through, but highly pervious; a shield had to be placed in front to block out water, allowing the workers to continue. Once the physical tunnel was constructed, a second layer of concrete was added, to seal it.

But still, that material doesn’t always hold. “There is no such a thing as a tunnel that doesn’t have leaks,” Horodniceanu declared. “It doesn’t exist. Eventually, water finds its way.” Especially in tunnels that were built more than a hundred years ago. And once water gets in, it affects everything that’s inside the tunnel—the signals, the lights, and all of the other electrical utilities that can turn a Monday morning commute into a hellfire.

“It’s not that complicated to fix the leaks. It’s more complicated to change everything that’s in there,” adds Horodniceanu. “In the tunnels, you have these benches on one side, the evacuation bench. Inside this bench are gazillions of tubes that are carrying all kind of systems, and number one, they are old. So sometimes the concrete crumbles, because it’s old, and was exposed, even more now with humidity, but then water that came in.”

Horodniceanu says the work planned during the L train shutdown will address these two problem areas, with modern-day material that plugs up water penetration on outside, and a total rewiring of the utilities that run through the tunnel. The latter is time-consuming, he says, requiring multiple trades who have to work in conjunction, to get everything up and running fast. Finishing in 15 months—the timeline given by the MTA for the tunnel’s work—”is doable, but ambitious,” he added.

One of the major issues back then was also air pressure. Famously, when building the tunnel leading up to the Brooklyn Bridge, at least five workers died from “the bends,” or decompression sickness. In another occasion, a shield ‘blew out’ due to pent-up pressure, sending a man named Richard Creedon soaring out of the 4 and 5 train tunnel, into the East River, and up in the air. He survived, and became a local legend.

Tunnels in 2017 are, of course, built a little differently. A good example is the Hudson Tunnel Project, a plan to build two new tunnels underneath the Hudson in order to replace the existing century-old structure, which services Amtrak, and New Jersey Transit. Many people might know the larger Gateway Program’s predecessor, the ARC (Access to Region’s Core) project, that New Jersey Governor Chris Christie sunk, pissing off a majority of his state in the process. (Grumblings over the outgoing governor are background noise on any delayed NJ Transit train.)

“The Hudson River tunnel that’s existing now is increasingly unreliable, and a single point of failure for 10 percent of the nation’s GDP,” Craig Schulz, the Gateway Program spokesperson, told me. “Four-hundred-and-fifty trains a day, 200,000 commuter and passenger trips made every day, rely on this 106-year-old asset. This thing was built before the Titanic set sail, when the Wright Brothers were switching from the Model A to the Model B flyer.”

Schulz, like many others, referred to it as the “most urgent infrastructure program in America.” “It needs to be replaced,” he added. “It needs to be rebuilt from the inside out, and there’s no alternative.”

In order to do that, the design for the Hudson River Tunnel includes four Tunnel Boring Machines (TBMs), which, if you haven’t already seen the videos, are basically these massive drills that look like something you’d see someone driving in Mad Max. Attached to the TBMs are conveyor belts, which takes out the river muck and rock. As the machine bores deeper into the earth, workers follow behind, adding in the decor, like the lighting, tracks, and concrete finishes.

The two tunnels are three miles long, and require two TBMs each, which are custom-built for their respective terrain. The Palisades, which one tunnel will go through, has a hard rock surface, requiring a different cutting head than the other tunnel underneath the riverbed. The construction and operation of the TBMs make up a significant portion of the project’s estimated $12.9 billion price tag. (The project is currently finishing its environmental impact statement, and awaiting funding.)

Considering that technology, one might be wondering how subway tunnels built by hand nearly a hundred years ago have sustained billions of passengers for this long. But it’s not the original design that’s causing any of the issues.”It’s just that it’s old, and as you’re well aware, New York doesn’t close their subways,” Michael Wyetzner, an architect at Michielli+Wyetzner, who has written on the topic, told me. It’s in continual operation, which makes it even more challenging, and puts more wear and tear on it.”

In fact, he argues that the structural engineering that went into those tunnels was “really kind of brilliant,” a marvel of the Industrial Age build. He then mentioned the cut-and-cover method used underneath city streets, no further underground than a basement; engineers cut trenches on the side of the road, lifted up the cement, laid down tracks, and then put the road back on top. “It’s very American. It’s very New York,” he continued. “It’s pragmatic, and very, ‘Just get it done!’ And then they’d decorate it with some nice tiles, which I kind of get a kick out of.”

But like with any engineered construction, Wyetzner added, its utilities require maintenance—something that, critics say, the agency hasn’t funded properly in decades. And the result of that was seen by millions of passengers Monday morning. “It’s like a car—if you maintain your car, it’ll last much longer than if you don’t do anything,” Wyetzner told me. “That’s what really causes the delays and breakdowns. Without maintenance, everything tends to break down at once.”

Follow John Surico on Twitter.

An earlier version of this article misstated the year Hurricane Sandy hit New York. It was 2012, not 2013.

More

From VICE

-

Screenshot: Epic Games -

Credit: Google -

-

KINGSTON UPON THAMES, ENGLAND – JULY 8: Yungblud performs live on stage during the 'Up Close And Personal' tour at PRYZM on July 8, 2025 in Kingston upon Thames, England. (Photo by Katja Ogrin/Getty Images)