Last week, I put a bounty on photos of Apple’s “iPhone Calibration Machine,” a device in the back of every Apple store that allows the company to monopolize certain types of iPhone screen replacements and could be immensely important if the company ever decides to integrate its fingerprint sensor into the screen of the phone.

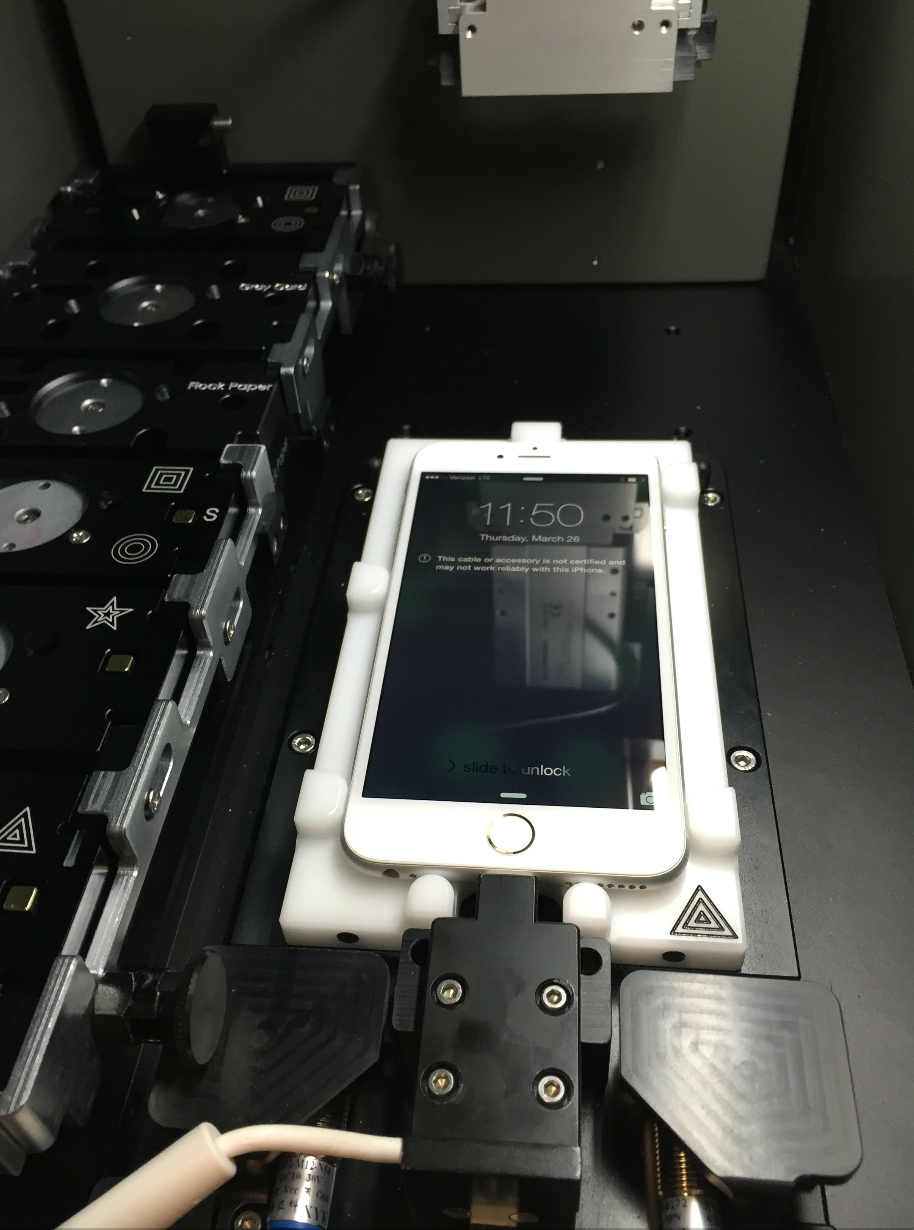

An anonymous tipster who used to work at the Apple Store snapped a photo of the machine and sent it to me. Here it is:

Videos by VICE

And here’s the outside of the machine (photo taken by a separate tipster):

As described by a third source, Apple started using these soon after the release of the iPhone 5S.

“It was a big clunky machine that honestly looked like someone built it in their backyard,” a former Apple Genius told me. “There were different ‘moulds’ that different iPhone models would go into before going in the machine, and it would take around 30 minutes … there was some weird liquid that needed to be placed in the machine that we would have to wear gloves with to fix it. Lots of gas type valves and whatnot. It literally looked like some backyard home job. Not very Apple-like at all.”

Read more: The Next iPhone Could Put 15,000 Independent Repair Shops Out of Business

The shapes you see on the left are for calibrating the phone’s camera, and “flock paper” and “gray card” are for calibrating the colors on the phone’s screen. Apple did not respond to a request for comment for more information.

It’s not surprising that Apple has proprietary technology to test iPhone repairs before they’re given back to customers, but the most important thing the machine does is allow a new Touch ID button to be paired with an old device. The machine is hooked up to an iMac, which connects the phone to an internal Apple server and allows the sensor to be recalibrated. This is something that no independent repair shop can do, and so it has allowed Apple to remain the only company that can fix broken screens without physically swapping old Touch ID buttons from the old screen (much more on that here).

Listen to Radio Motherboard’s episode about the right to repair.

“It would be great if a machine like that were available to independent repair shops,” Justin Carroll, CEO of Fruit Fixed, an independent smartphone repair shop in Richmond, Virginia told me. “If we’re testing a battery or swapping a screen it would make our lives a lot easier. At the very least, it’d help if Apple open-sourced its diagnostic modes to other people.”

“Imagine if every car we bought, every time you wanted to change the oil you had to take it to the dealer,” he added. “It’s just not realistic, and it monopolizes aspects of their business that are rarely good for their consumers.”

Subscribe to pluspluspodcast, Motherboard’s new show about the people and machines that are building our future.

More

From VICE

-

WWE via Getty Images -

Lexie Moreland/WWD via Getty Images -

Camp Snap -

Juiced